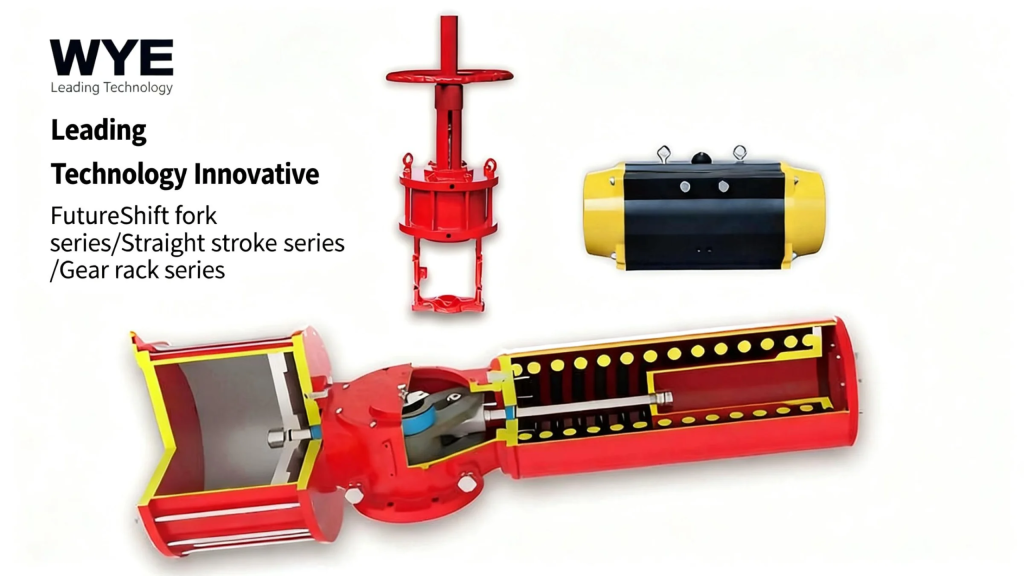

Product Center

A leading enterprise in China's valve industry, specializing in the research, development, production and sales of various valves, providing high - quality valve products and solutions for multiple industries.

Cooperation Case

WYVALVE aims to attract the most talented individuals in the valve field and offer them rich job experiences and career development opportunities. While working at WYVALVE, you'll have the opportunity to engage in the research, development, production and sales of various valves, gain insights into advanced valve technologies, and broaden your professional horizons in the valve industry.

News Center

Learn more about WYVALVE News, Valve Industry News, Valve Service Support, etc.

Latest News

Why WYEVALVE

WYEVALVE has achieved remarkable progress in the valve industry over the years, which is largely due to the dedicated efforts of our team. Therefore, we strive to ensure the satisfaction, motivation, and personal as well as professional growth of every employee.

Company Profile

Founded in 2016, Shanghai Wangye Valve Manufacturing Co., Ltd. is a professional industrial fluid control manufacturer with nearly a decade of experience, integrating R&D, intelligent production, sales, and customized solutions. Leveraging Shanghai’s advanced manufacturing advantages, we’ve built a reliable brand across petrochemicals, power, metallurgy, water treatment, and new energy industries, offering gate/ball/butterfly valves and tailored solutions for harsh conditions. Backed by advanced equipment, full-process quality control, and ISO certifications, we adhere to "Integrity, Quality, Customer Focus, Innovation" and provide comprehensive services, striving for long-term cooperation and continuous technological upgrading.

Talent and Efficient Team

WYE always insists that employees are the most valuable asset of the enterprise and the future of WYE; Adhere to prioritizing talent selection, education, and utilization in the development of enterprises; introducing talent as the highest return investment behavior. We regard talent as the primary resource for effective management, and pursue a high degree of harmony and unity between employee personal development and enterprise development.We encourage you to have a special perspective, think independently, and be good at organizing resources from all parties. Always maintain a responsible attitude towards results and a positive team spirit that is willing to share in every task.

High End Processing Equipment Creating Excellent Product Quality

Advanced automated production equipment and sophisticated assembly line production demonstrate first-class quality.Technical experts directly participate in production to ensure the concealment and reliability of the product.The increasing awareness of high-quality products and the continuous supply of industrial products have made WYE constantly changing.No matter how the world changes, the persistent spirit of excellence among WTE people remains unchanged.

Fine Selection and Strict Control

During the production process, the company strictly adheres to the requirements of the ISO9001 quality management system for its operations. By optimizing quality inspection work to ensure quality stability and strengthening customer service management, the company’s product quality pass rate has remained 100% for many years. We will never let unqualified products leave the factory. We believe this practice is not only a responsibility to our customers, but also to our own brand.

Warehouse Strength

In our facility, raw materials (including core components and packaging supplies) are strictly controlled via a real-time digital inventory system—tracking batches, shelf life, and storage conditions to boost traceability and cut waste. Semi-finished products, post-preliminary quality checks, are stored per strict industry standards: labeled with progress/inspection records to avoid cross-contamination and damage. Finished products are sorted into specialized warehouses by type, market, and delivery schedule, streamlining picking and reducing dispatch delays. This standardized process effectively boosts efficiency: cutting redundant steps by 30%, shortening fulfillment cycles by 20%, and minimizing inventory/shipment errors.

Customized Solutions & After-Sales Support

Tailored to the distinct demands of industries like petrochemicals, new energy, and metallurgy, WYE provides personalized industrial fluid control solutions—covering pre-project demand assessment, customized valve design (matching specific working conditions like pressure or medium type), and on-site technical consultation to align with clients’ operational scenarios. Additionally, we offer comprehensive after-sales support: including on-site installation guidance, regular equipment maintenance inspections, and 24/7 responsive fault troubleshooting, which ensures the stable operation of clients’ systems and strengthens long-term cooperative partnerships.

EXHIBITION & PROJECTS

COOPERATIVE PARTNER